When it comes to the longevity of certain electronic components, there is one question that frequently arises within the realm of capacitor technology: What is the average lifespan of electrolytic capacitors? As crucial elements in numerous electronic devices, these capacitors play a vital role in storing and releasing electrical energy. While their endurance and reliability are widely acknowledged, it is essential to explore the factors that influence their lifetime without using commonly associated terms.

Discovering the Secrets of Capacitor Longevity

One of the critical determinants of any electronic component’s lifespan lies in its inherent durability. Capacitors, often referred to as electrical energy reservoirs, are no exception. However, relying solely on the strength of the capacitor’s materials does not provide the complete answer to their longevity puzzle. Another significant factor to be explored is the intricate relationship between external conditions, such as temperature fluctuations and operating voltage, and the capacitor’s overall health.

Temperature Influence and the Invisible Time Thief

Without realizing it, temperature acts as an invisible time thief that gradually reduces the lifespan of capacitors. Whether we are talking about extreme heat or drastic cold, these fluctuations in temperature can significantly impact the longevity of electronic components. For electrolytic capacitors, excessive heat, in particular, can accelerate the aging process, resulting in a premature failure. In contrast, low temperatures may slow down chemical reactions within the capacitor, potentially prolonging its functional life. Understanding and managing temperature fluctuations is, therefore, vital in ensuring extended longevity for these capacitors.

Factors influencing the lifespan of electrolytic capacitors

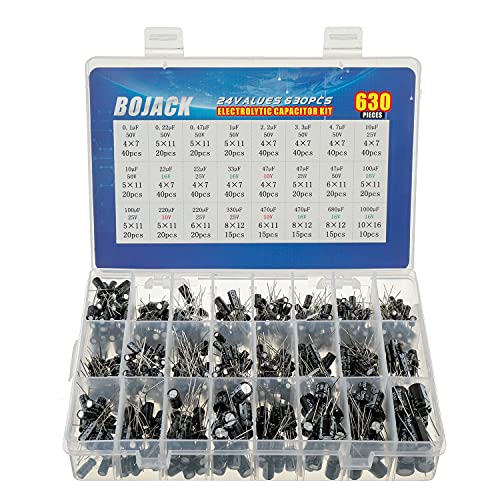

When it comes to the durability and longevity of electrolytic capacitors, various factors come into play that can significantly impact their lifespan. These factors are crucial to understand for anyone working with or relying on these components in electronic devices and systems.

1. Operating temperature

One of the primary factors influencing the lifespan of electrolytic capacitors is the operating temperature. Excessive heat can accelerate degradation and drying of the electrolyte, leading to a shorter lifespan. It is vital to ensure that the capacitors are operated within their specified temperature range to maximize their longevity.

2. Voltage stress

The voltage stress experienced by electrolytic capacitors also affects their lifespan. Higher voltage values can cause internal damage and degradation, leading to premature failure. Designers and engineers must carefully consider the voltage ratings and ensure that the capacitors are not exposed to levels beyond their limits.

3. Ripple current

Ripple current, which refers to the alternating current component in a circuit, can have a significant impact on the lifespan of electrolytic capacitors. Higher ripple currents can increase the heating and stress on the capacitors, thereby reducing their lifespan. Implementing proper circuit design and selecting capacitors with suitable ripple current ratings are crucial in mitigating this factor.

4. Aging and shelf life

Electrolytic capacitors have finite lifespans due to aging effects. Over time, the chemical processes within the capacitors can lead to changes in their electrical characteristics, resulting in reduced performance and eventual failure. Additionally, the shelf life of unused capacitors can deteriorate if they are stored for extended periods beyond their recommended timeframes. It is essential to consider these aging effects and adhere to proper storage practices to maintain optimal capacitor lifespan.

5. Quality and manufacturing defects

The quality of electrolytic capacitors and the presence of manufacturing defects can also significantly impact their lifespan. Poor-quality materials, inadequate manufacturing processes, or subpar quality control can result in capacitors that are prone to premature failure. Choosing reputable manufacturers, performing rigorous quality checks, and sourcing from trusted suppliers can help mitigate these issues and ensure longer-lasting capacitors.

Understanding these factors and their effects on the lifespan of electrolytic capacitors enables engineers, designers, and users to make informed decisions, implement appropriate mitigation strategies, and maximize the reliability and longevity of electronic systems and devices.

Operating temperature and thermal stress

One important factor to consider when discussing the lifespan of electrolytic capacitors is the operating temperature and the associated thermal stress they experience. The temperature at which a capacitor operates can have a significant impact on its performance and longevity.

Extreme temperatures can affect the internal components of the capacitor, leading to degradation and potentially reducing its lifespan. High temperatures can cause the electrolyte fluid inside the capacitor to evaporate or break down, resulting in a decrease in capacitance and an increase in internal resistance.

Conversely, low temperatures can cause the electrolyte to freeze or solidify, which can also impact the capacitor’s performance. Extreme temperature fluctuations can further worsen the thermal stress experienced by the capacitor, potentially accelerating its aging process.

It is important to note that capacitors are typically rated for specific temperature ranges, referred to as the operating temperature range or storage temperature range. Operating outside of these specified ranges can lead to accelerated degradation and premature failure.

- Choosing capacitors with a higher temperature rating can increase their resilience to thermal stress and potentially extend their lifespan.

- Proper thermal management, such as adequate ventilation and heat sinks, can help ensure that the capacitors operate within their rated temperature range.

- Electrolytic capacitors used in high-temperature applications may require additional consideration and careful selection to ensure optimal performance and longevity.

- Thermal stress can also be influenced by other factors such as the application’s duty cycle, load conditions, and ambient temperature.

In conclusion, the operating temperature and thermal stress play a crucial role in the lifespan of electrolytic capacitors. Understanding the temperature limitations and implementing proper thermal management strategies can help maximize their performance and extend their longevity.

Electrolyte Quality and Aging

In the context of the topic on the lifespan of electrolytic capacitors, it is important to understand the role of electrolyte quality and its impact on the aging process. The quality of the electrolyte used in capacitors plays a crucial role in determining their longevity and reliability.

Effect of Electrolyte Quality

The electrolyte, which is a conducting solution, acts as the medium for the flow of current within the capacitor. It not only provides the necessary ion movement for charge storage but also affects the overall performance and lifespan of the capacitor.

The quality of electrolyte determines its ability to withstand various environmental factors such as temperature, humidity, and voltage fluctuation. It also affects the stability of the chemical composition within the capacitor, preventing undesired reactions and degradation.

Aging Process and Electrolyte Quality

Over time, electrolytic capacitors undergo an aging process due to various factors, including the quality of the electrolyte. With continuous usage, the electrolyte can become chemically unstable or deteriorate, leading to a decline in the performance and reliability of the capacitor.

Poor electrolyte quality can accelerate the aging process, causing the capacitor to experience an increase in equivalent series resistance (ESR) and a decrease in capacitance. This can result in decreased efficiency and compromised functionality of electronic devices utilizing such capacitors.

Conclusion: Ensuring high-quality electrolyte and monitoring its condition is crucial in maximizing the lifespan and reliability of electrolytic capacitors. By maintaining the stability of the electrolyte, the aging process can be slowed down, allowing the capacitors to perform optimally over an extended period of time.

Voltage and Ripple Current Ratings

In the realm of electrolytic capacitors, an important aspect to consider is their voltage and ripple current ratings. These specifications play a vital role in determining the operational limits and the overall lifespan of these components.

When it comes to voltage ratings, electrolytic capacitors are designed to operate within a specific range of electrical potential difference. Exceeding the recommended voltage can lead to the breakdown of the capacitor, resulting in premature failure. It is crucial to carefully select a capacitor with a voltage rating that matches or exceeds the requirements of the circuit to ensure its longevity.

Similarly, the ripple current rating is another critical parameter that needs to be taken into account. Ripple current refers to the fluctuating current that flows through a capacitor due to the alternating nature of the power source or the presence of noise in the circuit. Capacitors with higher ripple current ratings are capable of withstanding larger amplitude and frequency of ripple current without suffering from overheating or failure.

To assist engineers in selecting the appropriate electrolytic capacitor for a particular application, manufacturers provide datasheets that contain detailed information about voltage and ripple current ratings. These datasheets specify the maximum voltage that the capacitor can withstand, as well as the maximum allowable ripple current under specific operating conditions. Consulting these datasheets and understanding the voltage and ripple current requirements of the circuit is crucial in ensuring the long-term reliability of electrolytic capacitors.

| Parameter | Definition |

|---|---|

| Voltage Rating | The maximum voltage that a capacitor can safely handle without risking failure or breakdown. |

| Ripple Current Rating | The maximum amplitude and frequency of fluctuating current that a capacitor can tolerate without overheating or failure. |

Proper storage and handling practices

Ensuring the longevity and optimal performance of capacitors involves not only their selection and installation but also proper storage and handling practices. By following these guidelines, you can prolong the lifespan of your electrolytic capacitors and maintain their performance efficiency.

Storage:

When it comes to storing electrolytic capacitors, it is essential to consider certain factors to prevent degradation and potential damage. Capacitors should be stored in a controlled environment with moderate temperature and humidity levels to avoid excessive heat or moisture that could negatively impact their performance. Additionally, it is recommended to store capacitors away from direct sunlight and sources of electromagnetic radiation to prevent interference or degradation of their dielectric materials.

Handling:

Proper handling practices are crucial to ensure the longevity and reliability of capacitors. When handling electrolytic capacitors, one should always be mindful of their sensitivity to physical stress and mechanical damage. It is advisable to avoid exposing capacitors to excessive pressure, bending, or dropping, as these actions can compromise their structural integrity. Additionally, one should minimize contact with the capacitor terminals to prevent any potential damage caused by electrostatic discharge.

Another essential aspect of handling electrolytic capacitors is the consideration of proper polarity. Always ensure that the correct polarity is observed during installation, usage, and maintenance. Reversed polarity can lead to catastrophic failure, resulting in permanent damage to the capacitors and other circuit components.

Labeling and documentation:

Proper labeling and documentation of electrolytic capacitors are beneficial for long-term storage and easy identification. It is recommended to label capacitors with relevant information, such as their capacitance, voltage rating, and date of acquisition. This practice helps in keeping track of their lifespan, maintenance schedule, and replacement requirements, ensuring that capacitors are utilized within their specified operational range.

By paying attention to proper storage and handling practices, you can extend the lifespan of electrolytic capacitors, reduce the risk of failure, and maintain the overall efficiency of your electronic systems.